Approaching Supplier Quality Management with Intelligent Digitisation - An Overview

Today’s customers carry a heightened awareness of how products are made and where key inputs are sourced. They expect accountability and transparency. Given these expectations, supply chain compliance commands more attention and importance than ever before.

These expectations also present complex challenges in the form of rapidly emerging supply chain requirements. Regulatory requirements at the national and local level, multilateral trade agreements and the tightening of internal corporate policies are all factors that must be accounted for. Furthermore, companies have diversified their supplier base, justifiably so to minimize risk, but must maintain and ‘police’ more supplier relationships. Real-time visibility into your supply chain network, and effective communication and collaboration between businesses and their suppliers are crucial for successful supply chain management and compliance.

The barrier to achieving this is often the lack of a single source of truth that tracks progress. Information is largely shared via email because suppliers and customers rarely operate on the same systems. Communication on the common ground allows each party to collaborate effectively, track progress and glean insight for constructive improvements.

The Softools platform hosts applications that enable a collaborative relationship between your business and suppliers. Having one place for all participants in your supply chain to collaborate will bring visibility of issues, risks and actions. This also prevents important actions, usually lost inside a spreadsheet or inbox, from falling through the cracks.

Three solutions centre specifically around preventative and corrective actions and function as the connective tissue for a healthy supply chain:

The Non-Conformance Incident (NCI) app captures, tracks and reports on supplier non-conformances.

The NCI is linked to Corrective Action Requests (CARs) and is part of the overall supplier innovation or continuous improvement program. CARs capture, track and report on corrective actions associated with non-conformance or supplier-related issues.

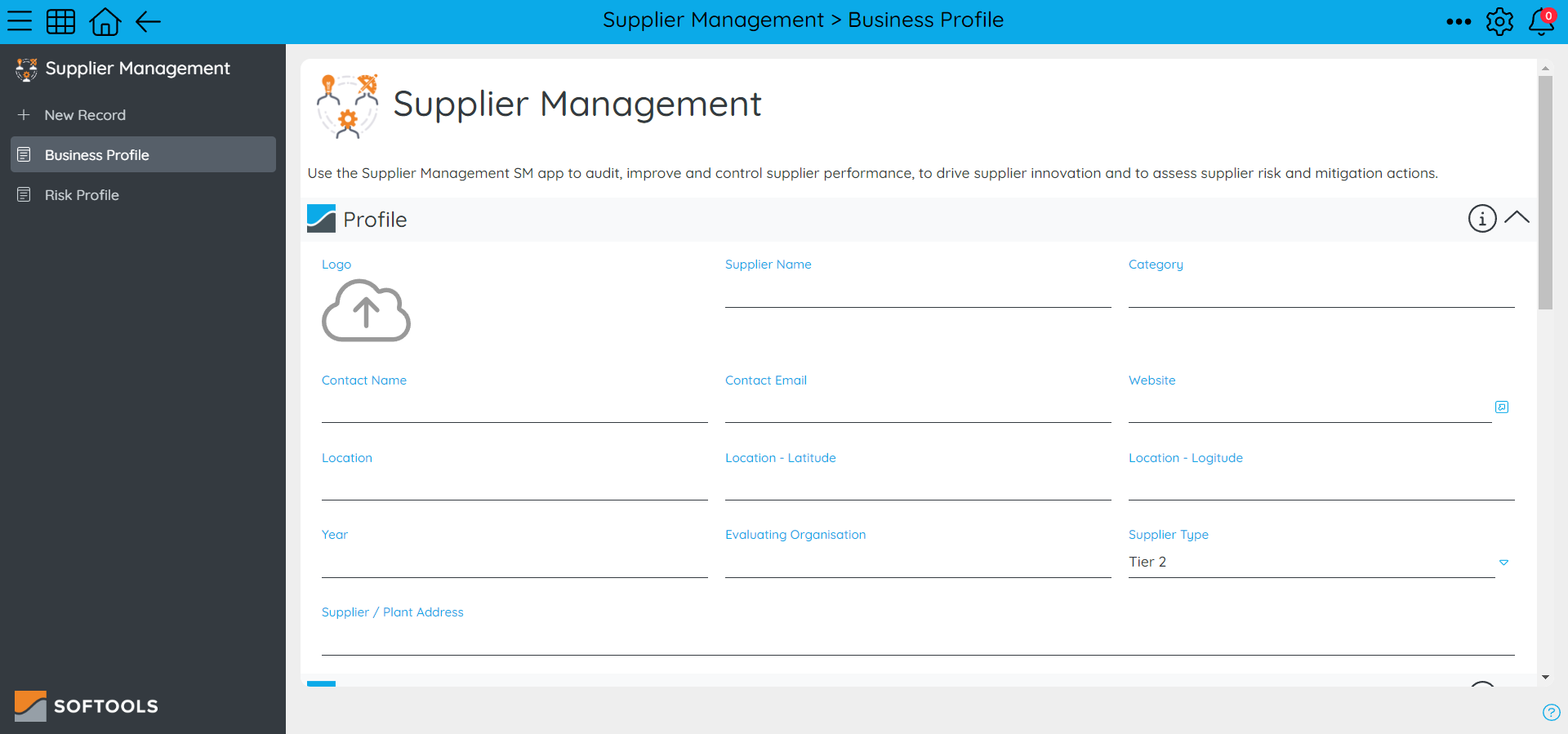

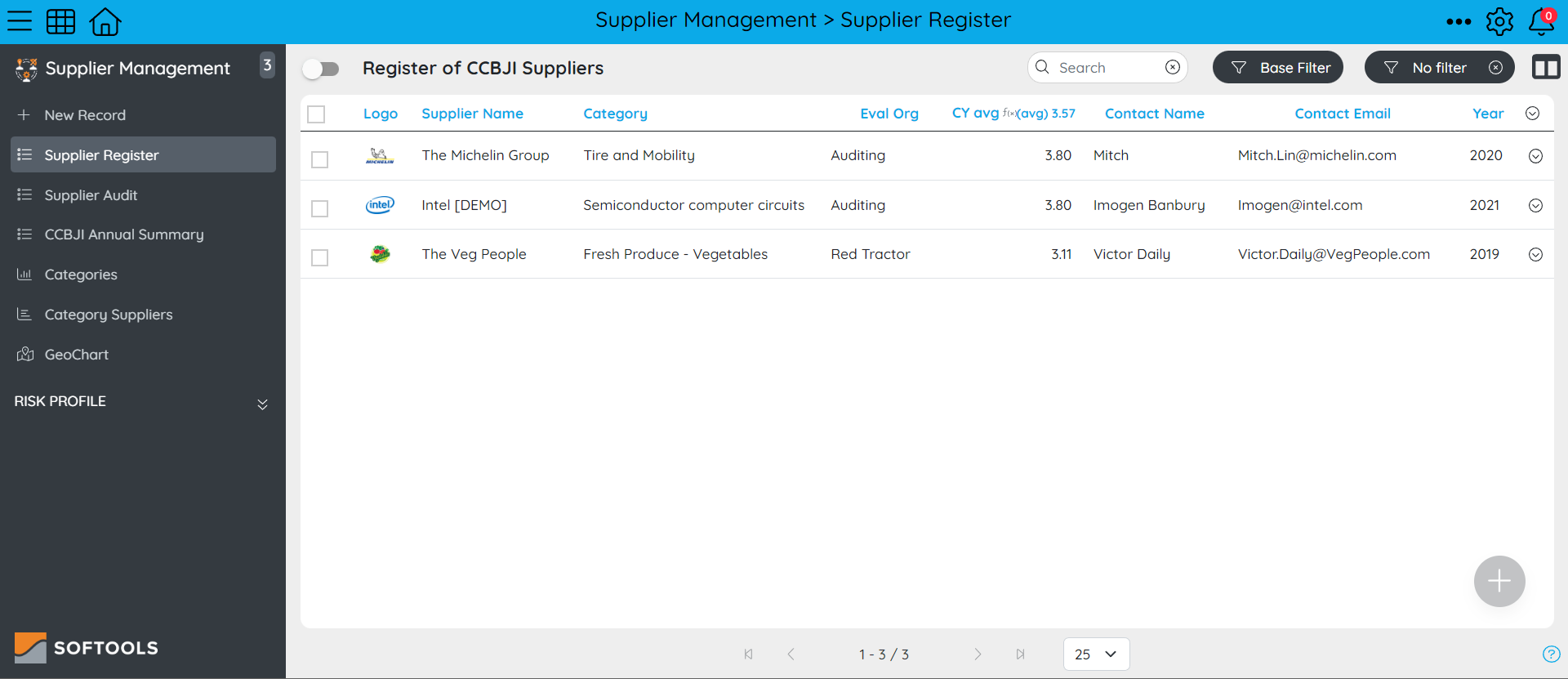

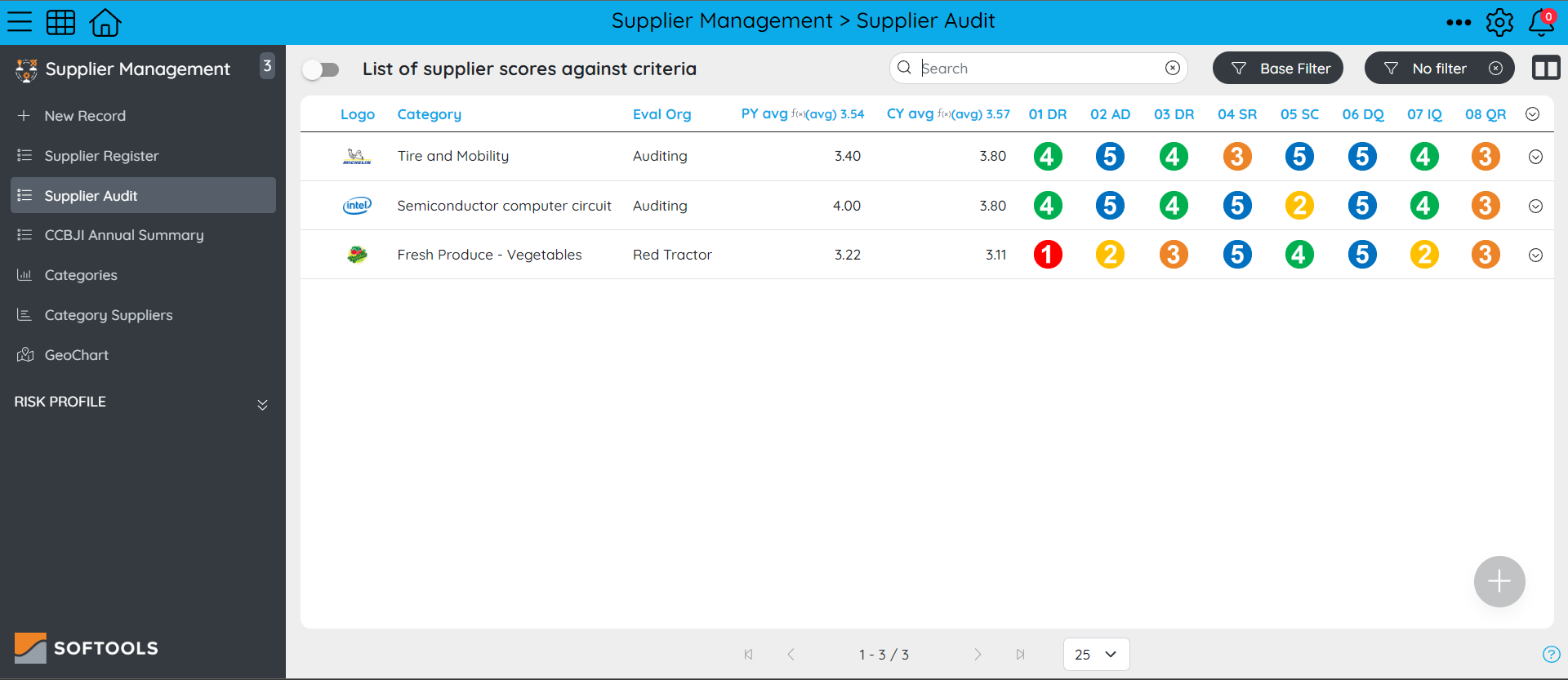

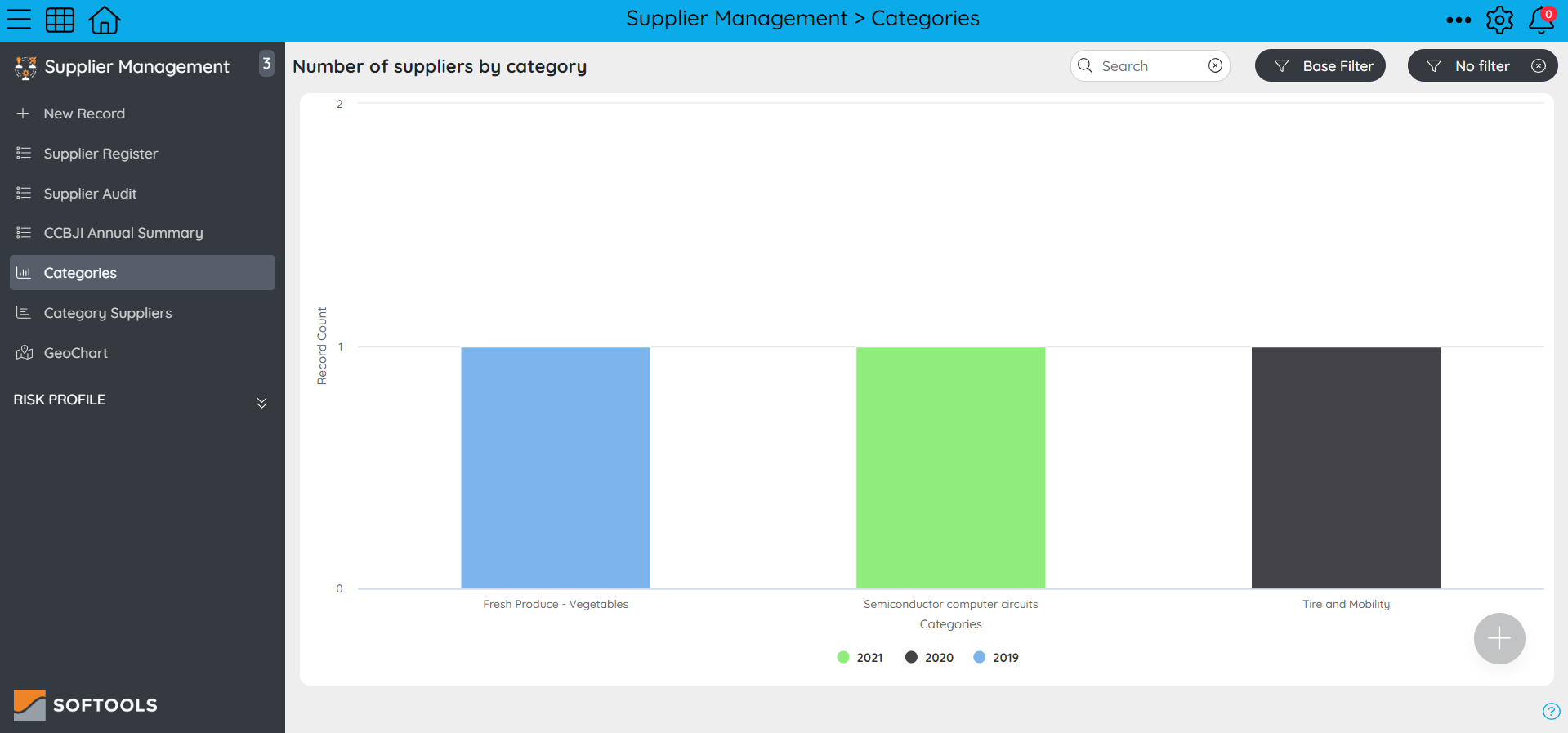

The Suppliers app anchors the supply chain management process. It assesses the performance of all suppliers in terms of outputs and the number of non-conformance incidents and plans improvement actions or innovation activities.

Companies can gain real-time, high-level visibility of supplier performance. The solutions are quick to deploy and use, and totally customizable. It is simple and fast to update and share supplier data or supplier compliance standards. This is of paramount importance in today’s changing landscape, and it is necessary to avoid losses associated with delays in identifying and acting on root causes.